The absolute encoder has higher anti-interference characteristics and higher data reliability than incremental encoders.

The absolute encoder has higher anti-interference characteristics and higher data reliability than incremental encoders.The absolute encoder determines the code by the mechanical position. It does not need to be memorized, does not need to find a reference point, and does not need to be counted all the time. When it needs to know the position when to read its position. Therefore, the absolute encoder has higher anti-interference characteristics and higher data reliability than the incremental encoder.

The absolute value encoder is divided into single-turn absolute value and multi-turn absolute value encoder.

The single-turn absolute encoder can only feedback the absolute position signal within a 360° circle, and if it exceeds 360°, it will output a repetitive encoding signal and lose its uniqueness. Therefore, when the measurement exceeds 360°, a multi-turn absolute encoder is required;

The internal function of the multi-turn absolute encoder is divided into two parts: single-turn angular position feedback and multi-turn detection. (Can use pictures to illustrate)

The internal structure of the multi-turn absolute encoder can be divided into two parts, single-turn angular position feedback and multi-turn detection. Single-turn angular position feedback is basically a single-turn absolute encoder. Multi-turn detection, as the name implies, its role is to identify the number of rotations of the mechanical shaft. Combining the value of this circle with the previous single-turn angular position to output, you can provide the required multi-turn absolute position feedback for the equipment system.

The methods to realize multi-turn detection include battery plus counting register, Wiegand principle counting, mechanical gear rotation encoding, etc.

The battery plus counting register and Wiegand principle counting have the advantages of easier technical implementation, low hardware cost, and simple lap recording function. The disadvantage is that the battery plus counting register will lose the lap record when the battery is dead or damaged; The Wiegand principle of counting, although the Wiegand coil is used, makes the accumulation of turns no longer need to rely on battery power and code plate readings. But it still cannot change the fact that its position code is calculated based on historical data. The register inner circle number and position record are accidentally lost due to electrical or software reasons such as line interference, storage failure, counting error, etc., which causes the failure of the encoder’s multi-turn absolute value feedback function.

Advantages of mechanical gear type multi-turn absolute encoder

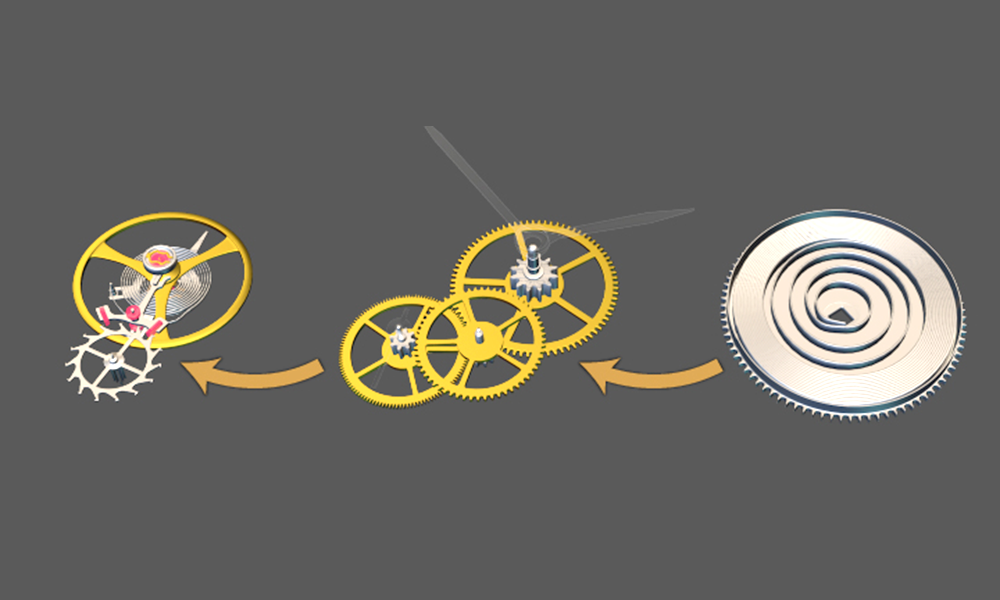

In contrast, the mechanical gear type multi-turn absolute encoder has higher reliability in the number of turns detection. There is a gear transmission structure in the mechanical real multi-turn encoder, which is similar to a Swiss watch, that is, a series of reduction gears that are gradually engaged with the main mechanical shaft. Each gear is connected to the upper gear and the main mechanical shaft. Relation of reduction ratio of integer multiples. Therefore, by identifying the rotation angle position of each gear, the number of rotations of the main mechanical shaft of the encoder can be detected.

The multi-turn encoder uses a pure copper gearbox. The pure copper gear makes the gear bite closer and closer, and the wear resistance, impact resistance, and vibration resistance are greatly improved, thus ensuring the high precision and long-term reliable operation of the encoder. It is not difficult to find that the absolute position feedback output by this type of encoder is directly measured based on the current mechanical physical transmission mechanism, rather than calculated based on historical records. It does not require batteries, and will not be subject to power failure, line interference, and program errors. …And so on the influence of the external environment, the reliability of signal feedback is achieved from the source of position detection.

Briterencoder is an expert of absolute rotary encoder.